- HOME

- Our Technicians

The excitement of weaving is created when the warp threads of technology intersect with the weft threads of the heart.

Since time immemorial, Japanese artisans have produced high quality textiles with delicate and careful handwork. No matter how high the machine specs may go, the ultimate deciding factor lies in the quality of the craftsmanship. In keeping with the saying, "God is in the details," the passion of our highly experienced artisans is the very essence of ALLTE CLOTH's craftsmanship.

Our name is not inscribed on our products. The technology itself is our brand. In the following secton we introduce some of the staff members who have created this brand. Each and every one of these people takes great pride in their work.

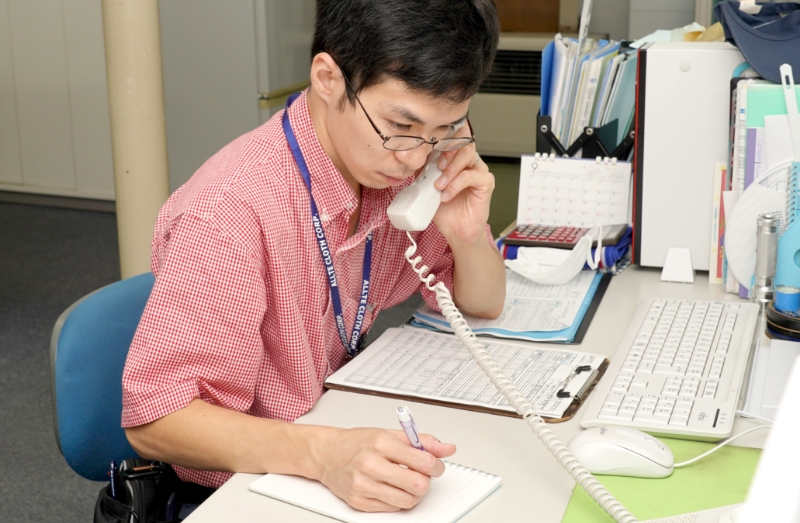

Through regular communication, we can transform "It can't be done" into "How can we do it?"

Entered the company in 2014Manufacturing Division, Production Control Department Yuki Kanno

For about a year and a half after joining the company, I experienced working on the frontlines of manufacturing in the Manufacturing Department. After that, I was reassigned and am now mainly responsible for production planning and progress management in the Production Control Department. I grasp the overall series of processes from order receipt through to production and shipment, prepare plans for the entire plant, and respond during times of trouble, which makes my job very rewarding as well as nerve-wracking.

Because ALLTE CLOTH is a manufacturing company, I feel that many of the staff members have an artisan's spirit. Personally I have always valued the importance of "taking on challenges without fear of failure and trying things out first," and I learned my job while being taught by my senior colleagues. Production control is a very difficult job, but when a problem arises, I gather a wide range of information from people at the site and consult with my superiors so that I can make the best possible decision. Sometimes customers can be harsh in their criticism, but I believe that my job is to "connect people with each other," so I try to keep my resolve and my thoughts about how I want to do things firmly in mind.

In the workplace, I try to communicate a lot. In the course of my work, there are urgent matters that need to be completed under tight deadline pressure, but even in such cases, by communicating with others on a regular basis, I am able to complete the work cooperatively from the perspective of "How can we do it?" rather than giving up on the assumption that "It can't be done." At such times, I strongly feel that this is a good working environment in which each of us can work with a sense of responsibility and pride. The president and the employees work closely together, and I am very happy that they can honestly share their thoughts and ideas with each other and raise their awareness in order to do a better job.

ALLTE CLOTH is a manufacturing company as well as being a company that can take on any challenge. Manufacturing is made possible through the accumulation of processes, and for this reason, the capabilities of each and every member of staff are indispensable. We continue to rise to the daily challenge of making "possible" what would normally be "impossible" through the cooperation of people in various fields. Why not explore your own potential at ALLTE CLOTH?

I want to learn my job and grow in an environment where people are taught unsparingly.

Entered the company in 2020Inspection Section 1, Manufacturing Department 1, Manufacturing Division Chihiro Ishiwata

While looking at some job postings that came to my high school, I was searching for a company that made something I knew, and I found that the company's products were being introduced as “used in the roof of the Tokyo Dome.” When I first learned that there was such a company in my hometown, I became interested in it, and that is why I started working here.

After I entered the company, I was assigned to the Production Control Department, which prepares invoices and orders raw materials and supplies, and was later transferred to the Inspection Section, where I am responsible for inspecting fabrics. The job of determining the types of defects is difficult, but I am learning by standing behind my seniors and confirming the whole process and inspecting the contents of defects with them. In addition to making visual inspections, I sometimes touch and inspect the products with my hands to get a sense of the defects.

What I try to keep in mind in my work is, “When in doubt, always check.” Nobody in this workplace would get upset with me for saying, “I don't understand this part.” Rather than that, they would be concerned that the problem would grow because they did not deal with it early enough. If my inspection determines that the product is okay, it will be shipped as our product, which means that I bear a great deal of responsibility. When I am not confident, I have the peace of mind of knowing that if I check with others, they will definitely support me, so I don't have to worry alone, and I feel I have an environment where I can easily call on others when I need help.

The senior staff, who generously teach me about their work, range in age from my parents' generation to my grandparents' generation, and they all watch over me attentively and warmly. Every day I learn important things not only about work but also about being a human being.

Another good thing about our company is that paid vacations are easy to take, which makes it easy to maintain a good balance between work and private life. When I get a ticket to attend a live concert by one of my favorite artists, I look forward to that day and work enthusiastically.

A basic rule of work is to learn by observing veterans as they work.

Your seniors will watch over you until you become proficient.

Entered the company in 2021Manufacturing Division, Manufacturing Department #1, Textile Section #1 Shion Wakabayashi

I joined ALLTE CLOTH because I enjoy physical exercise and precision work, and because I wanted to work in a factory. After I started working here, I found that the senior staff were very kind and the atmosphere was informal, which makes my days very enjoyable.

Currently, the basic tasks I perform include replacing weft yarns and mending the threads when warp yarns break. When weaving cloth, sometimes multiple threads break, and I am very happy when I am able to restore them to their original condition. I haven't performed any of the more difficult tasks yet, such as setting up machines, but I expect to learn them in future, and I would like to do so as soon as possible.

When I learn how to do a job, I begin by watching and learning the way seniors do it. If I miss even a single explanation, all the subsequent work will be delayed, so while I am being taught, I concentrate on listening while watching the senior's hands, and later I take notes to make sure I do not forget. It is easy to raise questions with senior staff, and if I don't understand something, they carefully explain it and watch over me until I am able to do it. In the past, they also provided follow-up when I made mistakes at work. When I am in a position to teach my work, I would like to be that kind of senior. Also, I was transferred to another company for two months in 2021 to see the yarn making process at first hand. I strongly feel that many of the things I learned there are still very relevant to my current work, and I am deeply grateful to have been given such an opportunity.

I feel that ALLTE CLOTH is a company with a good atmosphere where all the employees get along well with each other and can continue working for a long time. Moreover, this is a company that continues to challenge itself in almost any way it can and allows its employees to thrive. Why don't you join us here in taking on new challenges?

Your experience in various departments after joining the company will benefit you in subsequent work assignments.

Entered the company in 2019Manufacturing Division, Manufacturing Department #2, Inspection Section #2 Daisuke Adachi

Previously, while working for a glass fiber trading company, I considered changing jobs and decided to join ALLTE CLOTH. When I first joined the company, I spent about two years in the Manufacturing Department, where I gained experience in the manufacturing field. Although I already had a working knowledge of glass fiber and other materials from my previous work experience, at this company I have learned many new things and experienced a constant process of surprises and discoveries.

Currently, I work in the Inspection Section, where I inspect woven fabrics using an examination table. The process, called "defect correction," involves correcting loose or poorly twisted yarns. There are single yarns and twisted yarns made of several strands, and since defects inevitably occur during the weaving process, we use a magnifying glass and a needle to correct them one by one. After making the necessary corrections, we report them to the staff of the Manufacturing Department in an effort to make our products even better. I was assigned to the Manufacturing (Weaving) Department soon after I first joined the company, and I feel that the experience I had at that time was really good. I believe perspectives on inspection differ completely between those who know about the manufacturing process and those who don't.

The workplace atmosphere at ALLTE CLOTH is excellent, and the employees greet each other attentively. Since I believe that communication is very important in our work, I feel that I am working in a very good environment. Moving forward, I would like to continue to actively tackle a variety of challenges, including product inspection, in order to improve my own skills.

I imagine many people may feel uneasy if they lack previous manufacturing experience, including those switching from other industries, but even if you have no experience at all, as I did, you can do this job provided that you learn the skills. I hope you will step forward and take on this challenge.

I find it rewarding to create things that allow me to make the most of my personality.

Entered the company in 2021Preparation Section, Manufacturing Department 1, Manufacturing Division Fumi Hikichi

I am in charge of hanging the warp threads, a process performed before the power loom starts operating. The warp threads are threaded through the heddles, which open up to make room for the weft threads, and then run through the loom along the reed. ... If you have followed my explanation so far, I think most people would be confused by all the technical terms. When I first joined the company, I had no idea what the people in the workplace were saying to me.

Nevertheless, after I entered the company, my senior colleagues carefully taught me step by step, working together with me until I was able to reach a certain level of proficiency, which helped me increase the amount of work I was able to do.

My current work is performed at the start of the manufacturing process. When I see a finished product at the factory, I feel happy and think, “Wow, we made it.” This is especially true if it is a large product with lots of threads.

Although this task is a heavy responsibility and requires a lot of patience, as an initial flaw will affect all the subsequent processes, I have always liked making things, and I love detailed handwork such as beadwork. I worked in the service sector for a little while, but I realize that I am better suited to the manufacturing industry, where I can work diligently, and at a steady pace, as I am doing now.

This company has good communication, and it is easy to ask questions about things I don't understand, and there is an atmosphere in which everyone is willing to share their concerns about things they notice that might lead to trouble. If I need advice on anything, my supervisor is always willing to listen to me, so I am able to work with peace of mind. I would like to continue to work responsibly and increase the scope of what I can do.

I am steadily learning my job in a workplace where everyone greets each other cheerfully and without any inhibitions.

Entered the company in 2021Inspection Section 1, Manufacturing Department 1, Manufacturing Division Miho Sato

I have been involved in manufacturing ever since I began working, and my previous job was in the food-related manufacturing industry. My first encounter with ALLTE CLOTH was at Hello Work. When I stumbled upon a job opening and came to tour the factory, I was very impressed to see the process of weaving products on power looms. I was also impressed by how cheerfully the people at the company greeted me, which made me think, “I want to do my best at this company, too.”

My current job is to inspect completed products. I was puzzled at first because I didn’t understand what people were talking about due to the various technical terms being used, but thanks to my seniors who patiently taught me even when I asked the same thing more than once, I was able to learn the job little by little. Even if it takes a while to understand something, I can get a thorough answer, so I am able to work spontaneously in my own way without feeling nervous, even though it has taken me a while to get used to the environment.

Inspection is the final step in the process before shipping products, and involves checking products for width, density, thickness, fluff, etc., and visually checking for defects. In some cases, a magnifying glass is used to check quality. Since different cloths have different standards, I have a hard time grasping the characteristics of each one. I sometimes have to modify products, but I am not yet able to work as fast as my seniors, perhaps because I am too cautious. However, my goal is to be able to reliably and responsibly handle the work I have been entrusted with. Furthermore, in the future, I would like to learn new techniques and work to master them by observing the work of my seniors.

Another good thing about our company is that there is almost no overtime work and we can take plenty of time off. Since joining the company, I have more free time so I can cook for myself when I return home in the evening. I believe that if you can rest well and live a calm life both mentally and physically, you will be able to tackle your work with a positive attitude and say, “I'm going to do my best again today.”

Above all, I feel a strong connection with others and I am enjoying working in the second stage of my career.

Entered the company in 2013Manufacturing Division, Manufacturing Department #1, Inspection Section #1 Akira Suzuki

I worked at a gas station until I retired and then I joined ALLETE CLOTH through a referral from the Silver Human Resources Center. It is completely different from the work I experienced before, but I find the work here very easy to do.

I am in charge of small rolls, rewinding, and other tasks, and I learned my job while being taught by surrounding staff members. At first, I was unable to learn the work as well as I would have liked, and there were lots of difficulties, but I feel rewarded when I feel that I have done a job well on my own. Nowadays, I work with a sense of responsibility, paying attention to whether or not I am satisfied with my work.

Working at ALLTE CLOTH, I feel a strong connection with others. All the employees are kind and teach me about the work in a friendly manner. While some of you may be nervous, as I was, about working in a new environment after retirement, we have an environment here where you can experience a variety of new challenges, and I hope that you will rise to these challenges without fear of failure. I would like to continue working for as long as I am healthy enough to do so.